In August, the after-sales technicians of HV Hipot went to Xiangyang. The purpose of this trip was to provide impulse voltage debugging services for Xiangyang Power Supply Company.

After arriving at the site, with the assistance and cooperation of the customer, the installation of the lightning impulse voltage generator will be carried out.

On-site debugging of GDCY-400kV lightning impulse voltage generator

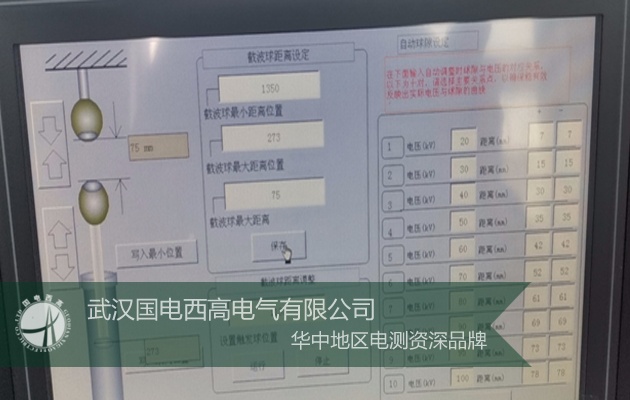

On-site ball distance calibration: body ball distance calibration and chopper ball distance calibration (3000/200/measured)

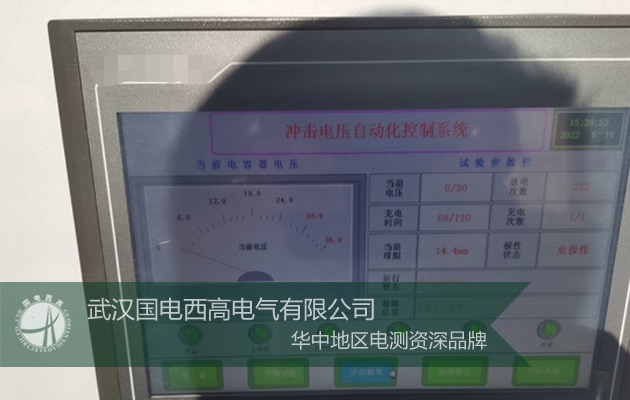

On-site running-in test: 30KV positive and negative polarity multiple tests (meet T1=1.2±30%/T2=50±20%us/TC=2 to 6us)

On-site strength test: rated voltage 80% output

On-site theoretical and operational training:

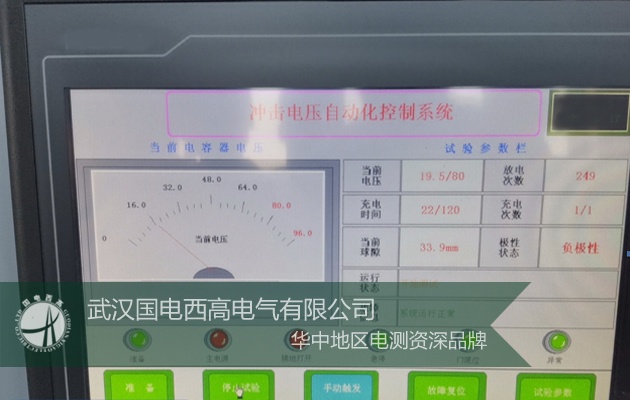

Customer practice – simulated test product test: 10KV power transformer

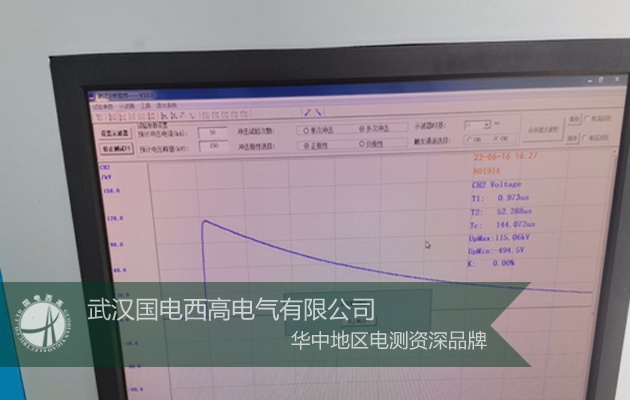

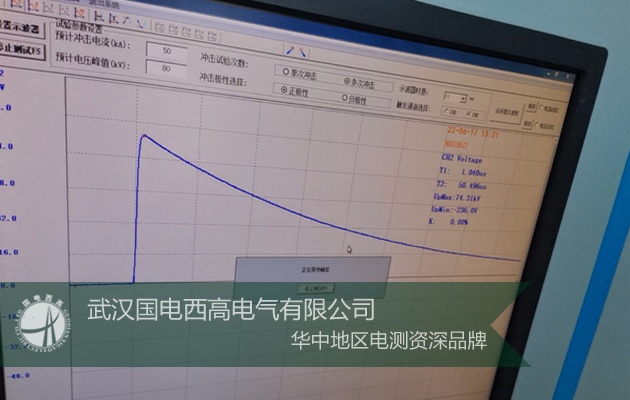

1. Full wave test

Test requirements: test voltage 75KV, waveform time T1=1.2±30%/T2=50±20%us

Field operation: using two-stage voltage output

On-site wave modulation:

Wave head resistance: 150Ω for the first level, 500Ω for the second level (2 1KΩ in parallel)

Wave tail resistance: 1st stage 45Ω, 2nd stage 45Ω

Test operation and waveform:

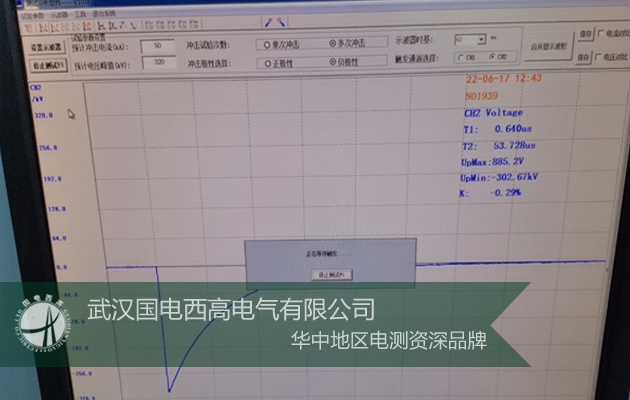

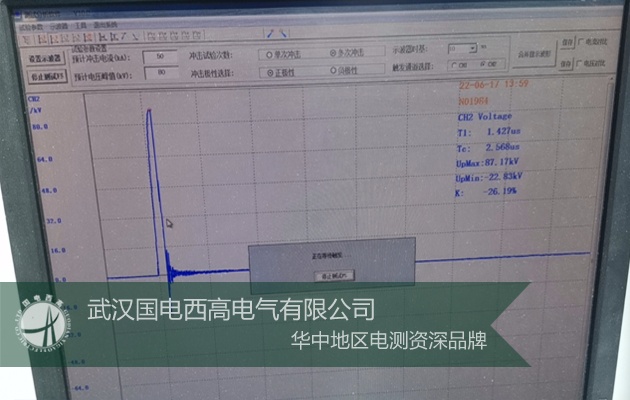

2. Cutoff test

Test requirements: test voltage 85KV, wave head time T1=1.2±30%, cut-off time TC=2 to 6us

Field operation: using two-stage voltage output

On-site wave modulation:

Wave head resistance: Level 1 75Ω, Level 2 500Ω (2 1KΩ in parallel)

Wave tail resistance: 1st stage 45Ω, 2nd stage 45Ω

Test operation and waveform:

After this series of training, the customer has an in-depth understanding of the whole set of equipment, which makes the customer more confident in the actual operation!

Post time: Aug-24-2022